Plain Bearing, as a Guarantee of Roller Conveyor Longevity

A conveyor is widely known as a mechanical means of automating and optimizing production processes. They gained widespread use at the dawn of the industrial revolution in the early 20th century. Henry Ford is considered a pioneer in this field, having organized the first conveyor production of automobiles in 1908. His continuous flow production of cars significantly accelerated the process and reduced the cost of producing a car.

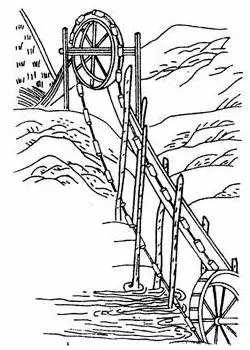

Since ancient times, humanity has strived to simplify and facilitate basic everyday tasks. For example, even in Ancient China, a device was invented that became the prototype of the modern conveyor - a chain mechanism for supplying water for irrigating agricultural fields. This early conveyor demonstrated the ingenuity of ancient engineers in developing tools to improve efficiency and productivity in agricultural tasks.

The principle of any modern conveyor is based on the movement of an object, in this case water, from point A to point B by means of a mechanical drive. This principle has been applied to a wide range of industries, from manufacturing to transportation, to automate and streamline processes.

The modern industrial world is difficult to imagine without the use of conveyor systems. Engineering thought has helped to expand the scope of their application and create dozens of types and subtypes of conveyor belts. Today, with their help, we can move objects in horizontal, vertical, and inclined directions; use conveyors at the stages of assembly, sorting or transportation; work with bulk or piece goods. The most widely used are belt, bucket, rope, screw, roller, and other types of conveyor mechanisms.

Roller Conveyors and Bearings

One of the most well-known types of conveyor systems is roller conveyors, or as they are also called, roller tracks. They are a system of rollers fixed on a common frame, over the surface of which piece goods are moved. Roller tracks can be found in everyday life in many areas of human activity. They are used on production lines, in postal sorting stations, in warehouses, and even at supermarket checkout stations. One roller track, or roller conveyor, consists of dozens or even hundreds of closely spaced rollers that are driven by a motorized method or under the influence of gravity. Each roller of the roller track rotates around its axis on two bearings. It is precisely the high-quality bearing that is the main element that determines the long service life of the roller track.

For example, one meter of a roller track used at a postal sorting station can contain about 10-15 rollers, rotating respectively on 20-30 bearings. The average postal sorting station, in any large city, is tens of meters of roller track and hundreds of bearings. Servicing such a number of ball bearings would entail the need for constant lubrication, replacement, and repair. Plain bearings in this situation are the most rational solution.

Technymon Plain Bearings for Roller Conveyors

Modern plain bearings, produced by the Technymon company worldwide, will be an ideal solution for the manufacturer of roller tracks, as they have a number of obvious advantages:

- do not require maintenance;

- do not require lubrication;

- durable;

- wide size range plus the possibility of producing plain bearings of custom sizes.

Technymon plain bearings have been produced since 1985 in Italy. Initially used in the automotive industry, Technymon bearings quickly spread their presence in mechanisms used in many areas of industry. Plain bearings for roller tracks and other mechanisms surpass the offers of other manufacturers in many parameters and have a number of competitive advantages.

If you are looking for plain bearings for roller conveyors, we strongly recommend that you pay attention to the range of Technymon bearings. For any questions that arise after reading this article, use the contact form, one of the phone numbers, or ask a question on LinkedIn.