Plain Bearing

by Technymon

A plain bearing is a mechanical element designed to reduce friction between two moving parts. Unlike ball bearings, which have balls and raceways, plain bearings are a solid piece with two working surfaces: an inner and outer race. Plain bearings are characterized by providing smooth gliding of one part relative to the surface of another.

Due to its simple design, plain bearings are a more economical alternative to rolling bearings, especially in applications with low rotational speeds.

In the modern technological era, plain bearings offer a wide range of applications in many industries. Technymon produces three main types of plain bearings:

- Self-lubricated: These bearings have a built-in lubrication system.

- Pre-lubricated: These bearings are pre-lubricated at the factory and require minimal maintenance.

- Polymer plain bearings: These bearings are made from polymers and are known for their low friction and wear resistance.

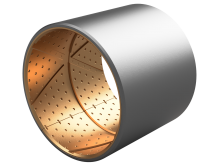

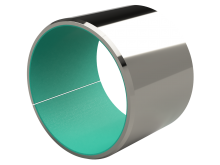

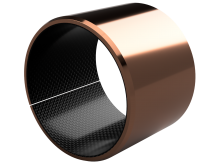

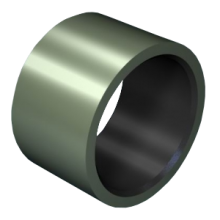

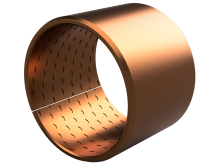

Pre-Lubricated plain bearings

BRM-10/80 Bearings

Bronze

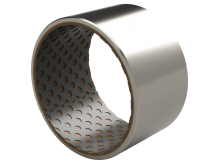

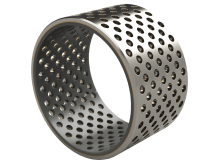

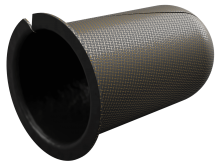

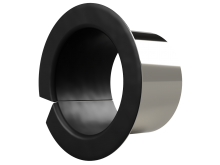

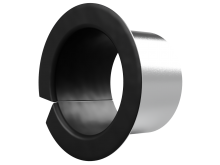

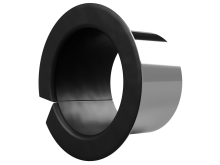

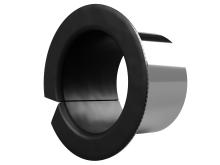

Self-Lubricated plain bearings

ML-2 Bearings

- PTFE impregnated Stainless steel AISI 316L mesh

- Stainless steel AISI 316L

- Sn or Zn protective layer

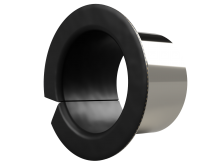

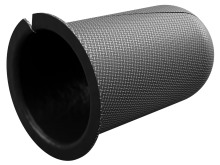

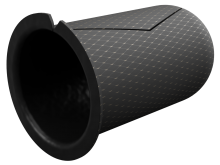

Polymer plain bearings

MP-G Bearings

- Thermoplastic material

- Solid Lubricant

- Fibres

Depending on the operating conditions of your mechanisms, you can choose the type of bearing that will provide maximum efficiency at minimal cost.

Applications of Technymon Bearings

For over 40 years, Technymon has been producing plain bearings in series and by individual request for various industrial consumer groups. Our bearings are most commonly used in mechanisms within the following industries:

- Automotive industry

- Oil and gas equipment

- Hydraulic equipment

- Agricultural machinery

- Construction and mining equipment

- Renewable energy production mechanisms

The Impact of Plain Bearings

Despite the long history of such a simple invention as the plain bearing, we still use them in everyday life. From simple door hinges to complex mechanisms in cars and airplanes, plain bearings remain an integral part of many machines and devices.

Plain bearings have a long history. The first examples of such supports were discovered by archaeologists in ancient mechanisms and tools. Ancient Egyptians, for example, used wooden bushings as bearings to move heavy stone blocks during the construction of pyramids.

With the development of civilization, plain bearings have been refined. In the Middle Ages, they were used in water mills, clocks, and other mechanisms. With the beginning of the Industrial Revolution, the need for reliable and durable supports grew significantly. This stimulated the development of materials science and design solutions.

Today, plain bearings are widely used in various industries: mechanical engineering, automotive, aviation, shipbuilding, and many others. They are used in internal combustion engines, pumps, compressors, turbines, and other mechanisms.

Pros and Cons of Plain Bearings

Advantages

- Low cost: Plain bearings are cheaper to produce than rolling bearings.

- High load capacity: They can withstand significant loads.

- High vibration resistance: They can operate under conditions of high vibration.

- High chemical resistance: A separate group of Technymon bearings is designed for long-term use in chemically active environments.

- Ability to operate at high temperatures: Plain bearings can operate at temperatures that are inaccessible to rolling bearings.

- Conductive properties: Some of the materials we use have high electrical conductivity, while the same bearing models can be made from dielectric materials.

Disadvantages

- Increased friction: Compared to rolling bearings.

- Limited service life: Due to wear of the working surfaces at high speeds. For the convenience of engineering teams, we have developed a plain bearing life calculator that takes into account many operational factors.

The choice of bearing type depends on the specific operating conditions of the mechanism: load, rotational speed, temperature, type of environment, and other factors.

Technymon's Continuous Development:

The development of technologies leads to the emergence of new materials and designs for plain bearings. In the future, we expect the emergence of more efficient and durable bearings with improved friction, wear resistance, and heat resistance characteristics.

Every year, Technimon units participate in industry exhibitions around the world. The main goal of such events is to present the latest developments of our technologists, new forms, and new properties. You can find a list of our upcoming events on the Upcomin Events page. We also invite you to join us on LinkedIn or Facebook.

Upcoming Events

We would be delighted to share our recent advancements in sliding bearing technology. To stay informed about upcoming events, please visit our events page or reach out to us via our feedback form or social media platforms.