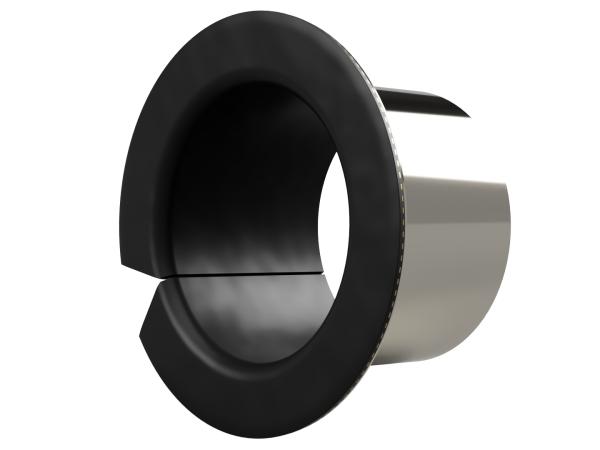

ML-1 Self-Lubricated Bearings

ML-1 bearings are unique composite bearings built with a woven/expanded bronze mesh embedded in PTFE (polytetrafluoroethylene). This combination offers several key advantages:

- Lead-free and environmentally friendly: The solid lubricants used in the PTFE comply with the European Parliament's "ELV" directive 2000/53/Ec, making them a sustainable choice.

- Low friction and high chemical resistance: Similar to pure PTFE, ML-1 bearings exhibit exceptional low friction and high resistance to various chemicals.

- Enhanced mechanical strength: The metallic backing layer provides the bearings with the necessary strength and formability for diverse applications.

- Excellent thermal conductivity: The composite structure of ML-1 bearings ensures efficient heat dissipation.

ML-1 bearings are available in various forms, including cylindrical bearings, flanged bearings, and washers, with thicknesses ranging from 0.75 mm to 1.50 mm (0.029 to 0.059 inches).

Operating Conditions

-

DRY -

OIL -

GREASE -

WATER -

PROCESS

FLUID

Please, fill this form for getting current Pricesheet and/or Drawings in DWG format. We will send you all files on your email.

All fields, which marked by an asterisk (*), are required.

Thank you for your interest in our company.

Characteristics

- Extra-thick sliding layer with woven/expanded metal mesh support embedded with PTFE helps in edge loading

- High calibration / sizing assembly to compensate higher tolerances of hinge hole and pin

- Electrically conductive to enable EDP (Electro-Phoretic Deposition), also available with notches

- Right fit according to requirement to achieve desired torque value

- Noise-free / smooth operation in assembly

Technical Data

| Maximum Specific Load Static | 150-300 N/mm2 |

|---|---|

| Maximum Specific Load Dynamic | 100-170 N/mm2 |

| Service Temperature Minimum | -200°C (-328°F) |

| Service Temperature Maximum | +180°C (+356°F) |

| Service Temperature Intermittent | +260°C (+500°F) |

| Maximum Speed Dry | 1.0 m/s (200 fpm) |

| Coefficient of Friction Dry | 0.07 - 0.17 |