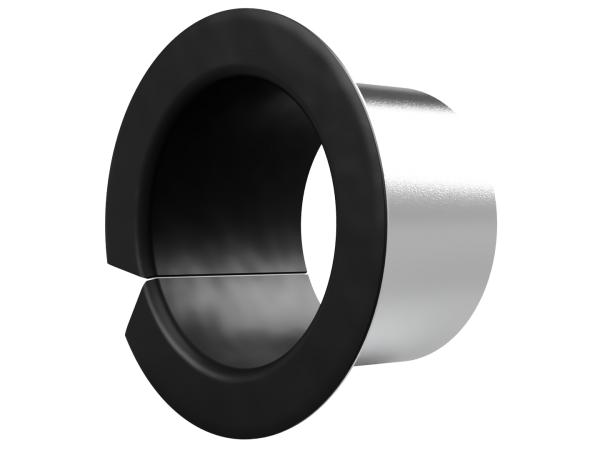

MR-5 ALC Self-Lubricated Bearings

MR-5 ALC bearings made with an innovative composite material. This material consists of a special tape made from compounded PTFE wrapped around alluminium cladded steel supporting shell. The PTFE tape made from carbon and graphite, which give the bearings these properties: self-lubrication, noise isolation, and minimal play.

The MR-5 ALC bearings come in two key versions:

- Version E: with a high surface conductivity PTFE sliding layer

- Version D: with a non-conductive PTFE sliding layer

MR-5 ALC bearings are characterized by the use of aluminium cladded steel as the supporting shell.

MR-5 ALC bearings come in various forms, including: Cylindrical bearings; Flanged bearings; Washers; Belts; Cast-to-size parts.

These bearings are available in standard thicknesses of 0.500 mm, 0.750 mm, and 1.000 mm.

Operating Conditions

-

DRY -

OIL -

GREASE -

WATER -

PROCESS

FLUID

Please, fill this form for getting current Pricesheet and/or Drawings in DWG format. We will send you all files on your email.

All fields, which marked by an asterisk (*), are required.

Thank you for your interest in our company.

Characteristics

- Thick sliding layer with uniformly distributed solid lubricants

- Good calibration/sizing assembly (zero-clearance)

- High surface conductivity with E version PTFE, not-conductive D version PTFE available with notches/dimples, to prevent paint bridge issues, 1Ω volume conductance can be achieved with proper surface contact

- With right fit, uniform torque can be achieved at the required value

- Thick PTFE layer helps in edge loading

Technical Data

| Maximum Specific Load Static | 60-200 N/mm2 (8700-29000 psi) |

|---|---|

| Maximum Specific Load Dynamic | 45-120 N/mm2 (6540-17400 psi) |

| Service Temperature Minimum | -200°C (-328°F) |

| Service Temperature Maximum | +180°C (+356°F) |

| Service Temperature Intermittent | +260°C (+500°F) |

| Maximum Speed Dry | 1.5 m/s (300 fpm) |

| Coefficient of Friction Dry | 0.06 - 0.3 |

| Maximum Dry Load Factor Continuous | 1.8 N/mm2 · m/s |

| Surface Resistivity E version PTFE | ~105Ω |

| Surface Resistivity D version PTFE | ~1014Ω |