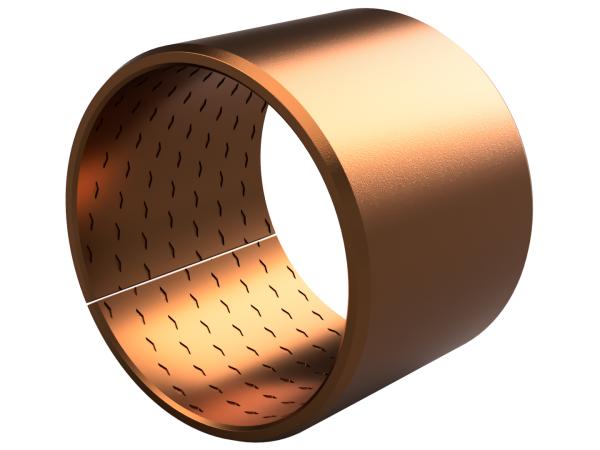

BRM-10/80 Pre-lubricated Bearings

Under BRM-10/80, Technymon introduces a range of full bronze sliding bearings. Bronze specification is according to UNI EN 1652 (CuSn8P) which is particularly suitable for sliding couplings with steel. This characteristic is highly improved by stamping and/or machine working the surface obtaining lubricant pockets, holes or channels to distribute and maintain the lubricant film between the pieces.

Central items of BRM-10/80 range are the cylindrical bushings (ISO 3547), plain or flanged; in a difference wall thicknesses. BRM-10/80 series includes all the sliding bearings normally used like thrust washers, sliding strips and in addition to these Technymon can offer a wide variety of special items to customer’s drawings.

Operating Conditions

-

DRY -

OIL -

GREASE -

WATER -

PROCESS

FLUID

Please, fill this form for getting current Pricesheet and/or Drawings in DWG format. We will send you all files on your email.

All fields, which marked by an asterisk (*), are required.

Thank you for your interest in our company.

Characteristics

BRM-10/80 sliding bearings offer many advantages, including the following:

- high load capacity

- very compact dimensions

- high chemical resistance to aggressive environments

- high thermal conductibility

- wide range of working temperature

- easy installation and maintenance

- wide availability of standard bushings

- possibility for special items

Design Data

To choose the right BRM-10/80 sliding bearing one must know the maximum applicable load, the sliding speed, the type and the intensity of the lubrication, the hardness and the roughness of the counter piece surface; after that the mechanical characteristics to consider are listed here below.

| Hardness HB 2,5/ 62,5/10 | 110-140 |

|---|---|

| Roughness Ra | <0,5 μm |

| Thermal conductibility | 60 W/m.K |

| Coefficient of thermal expansion | 20 x 10-5/°C |

| Coefficient of friction (with oil or grease) | 0.06 ÷ 0.17 |

| Service Temperature | -40°C to 150°C (-40°F to 300°F) |

| Maximum Speed (with oil or grease) | 2.5 m/s (500 fpm) |

| Maximum PV factor (with oil or grease) | 2.7 N/mm2 * m/s |

| Maximum work load Static | 150 N/mm2 |

| Maximum work load Dynamic | 60 N/mm2 |

Sliding Surface

BRM-10/80 sliding bearings must always be used with lubrication. For the applications where the lubrication can just be periodic grease must be adopted, while where the lubrication can be continuous a lubricant oil can be chosen. The different type of lubricant involves a different type of BRM-10/80 bearing sliding surface. When grease is adopted the bearing sliding surface must be requested with lubricant pockets, while with oil the sliding surface can be plain or with lubricant channels.

Lubrication

Lubrication is strictly needed for the correct use of BRM-10/80 sliding bearings; lubrication is also useful to prevent corrosion on the counter pieces. When the coupling is exposed to atmosphere or to aggressive environments it's advisable to adopt lubricant seals which always improve coupling service life.

Mounting

Base procedure for bushings mounting is to force them into their seats; there are some suggestion to follow:

- Machine a 1 mm seat lead - in with an angle of 20° (±5°)

- Clean and burr the pieces to couple

- Lubricate external bushing surface before mounting

- Check alignment between seat and bushing centre lines

- When 2 bushing are needed their junctions must be aligned

- Use a proper sized mandrel when possible.

- Mounting can be done with hydraulic or mechanical tools.

The mounting force (F) in Newton is shown in the attached table.

| Bushing Nominal Thickness 0,50 ÷ 1,00 mm | F = 300 x L (Length of bush) |

| Bushing Nominal Thickness 1,00 ÷ 1,50 mm | F = 500 x L (Length of bush) |

| Bushing Nominal Thickness 1,50 ÷ 2,00 mm | F = 700 x L (Length of bush) |

| Bushing Nominal Thickness 2,00 ÷ 2,50 mm | F = 900 x L (Length of bush) |

When mounting larger bushes it is advisable to use a mounting tool to support the bush. The tool diameter should be 0,3 ÷ 0,4 mm more than the bush diameter. If the bush is secured by using an adhesive, care must be taken to ensure that good quality adhesive are used and that it does not get onto the sliding surface.