Sliding Bearings in the Automotive Industry

The Manufacturer of solutions for automotive industry

In the dynamic world of automotive innovation, Technymon stands as a trusted partner, not merely a manufacturer of sliding bearings. We transcend the boundaries of traditional component supply, delving into the realm of comprehensive automotive solutions. Our expertise extends far beyond the bearing itself, encompassing a holistic approach that addresses the intricate challenges of vehicle design and performance.

Since our inception in 1975, Technymon has been an integral part of the automotive industry, consistently delivering exceptional products and services to renowned auto brands, independent manufacturers, and spare parts providers. Our unwavering commitment to quality and innovation has earned us a reputation as a pioneer in tribological technology.

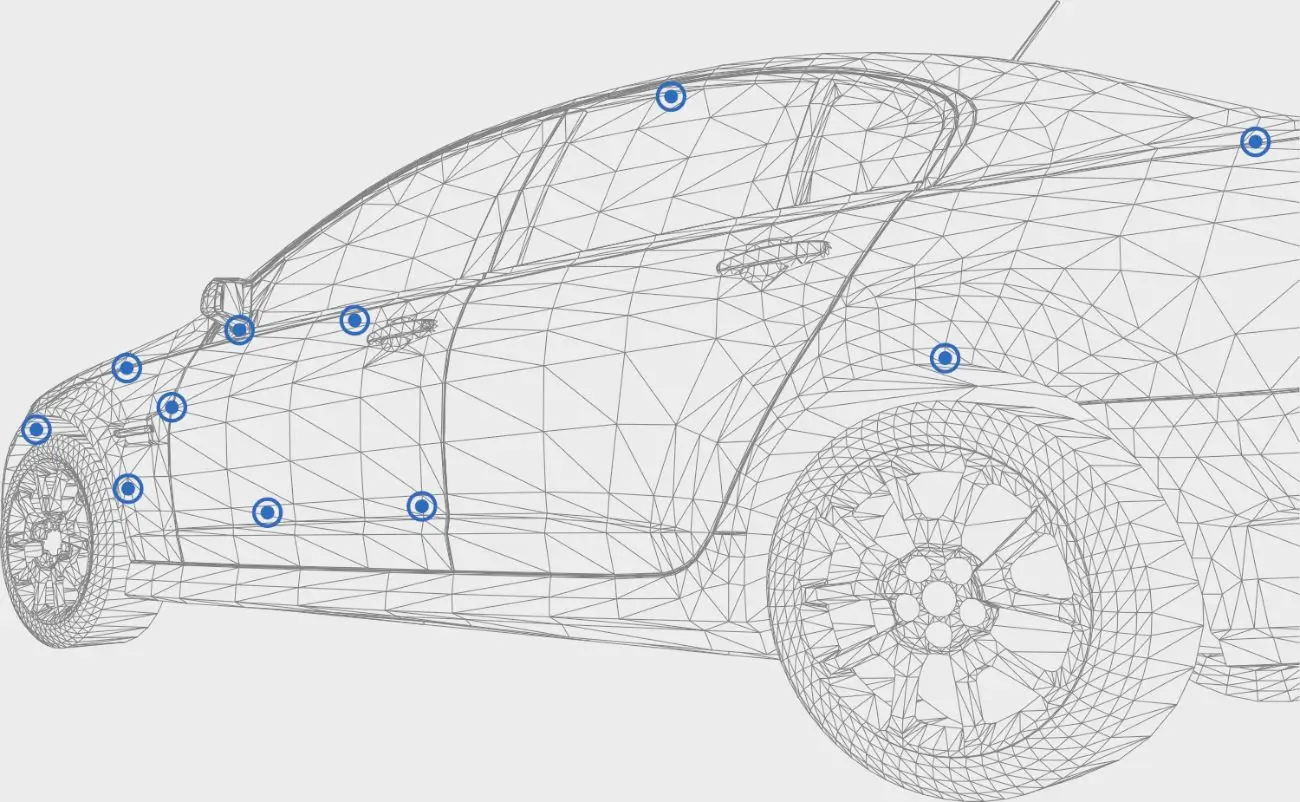

Where our Parts Go

- Door-, hood-, trunk- and tail gate hinges

- Seating system

- Steering system

- Pedals

- Light projection range

- Shock absorber

- Windshield wiper

- Automatic mirror

- Driveshafts, axies, brakes

- Powertrain, transmission, differentials

- Heating, A/C

- Engine components: E-Drive / E-Motor, Belt tensioners / Pulleys, Fly wheel, Fuel injection system, Oil / Water / Fuel

Get a Proposal

Technimon engineers will find the best solution for the application of our products in your production. Please fill in the simple contact form and our specialists will contact you as soon as possible.

Technymon supplied its first metal polymer sliding bearing into the Italian market in 1975 and since then the company has broadened its product range to all different fields of industries and applications. During the 1980’s the company started to focus more deeply on the automotive sector, putting a remarkable level of effort into performance and product quality and as a result in these years Technymon succesfully developed its business in a growing automotive industry and market.

In 1985 we established a wear test laboratory in our in Italy based plant, which has since been used to various types of testing related to the many applications concerning the automotive industries, with a world-class research and development facility. Over the past decade our Research and Development group has made efforts to enhance our wear test laboratory, and is now equipped with the latest design-modeling & simulation software and benchmarking equipment.

At Technymon we are continuously working on the tribological aspects to improve the frictional control technology, which directly results into less wear and higher life span for sliding bearings.

Our technical and sales team are in constant contact with our customers to respond quickly to any request raised by any of our clients from around the world.

Various Technymon products that are incorporated into automotive applications have functionality and performance characteristics that control friction and reduce energy loss. These are environmentally friendly as per ROHS (Restriction of Hazardous Substances), compliance products that contribute to reduced energy and resource requirements.

Thanks to our team effort Technymon products have become a well known brand in the global automotive industry. Naturally Technymon supplies a wide range of sliding bearings in terms of material, sizes and shapes and into numerous applications concerning the automotive sector. Through its cutting edge technology Technymon contributes to a healthy global environment, whilst adding an extra edge to vehicle safety and comfort.

- Roof top convertible

- Tail gate assembly

- Wiper assembly

- Hood hinges

- Door hinges

- Steering Columns & assembly gear box

- Seating systems

- Break pedal & clutches

- Engine & accesories

- Fuel injection systems

- Transmission & powertrains

- Pumps

- Shock absorbers, suspensions & ball joints

- Light regulation units

Add extra mile by using Technymon Plain Sliding Bearings

At Technymon we are doing continuous research to design a material which can sustain the demanding conditions of the automotive industries and applications, therefore Technymon sliding bearings are designed in a way which contains the following properties:

- High load carrying capacity

- Low coefficient of friction

- Our target to keep values of static and kinetic coefficient of friction as near to each other as possible

- A degree of self alignment to avoid edge loading

- Low maintenance i.e. lubrication free

- Sealed bearing surface to prevent ingress of dirt

- Corrosion resistance

- Long life

- Ability to withstand wide range of temperatures

- Easily changeable parts in case of wear