Composite and Journal Bushings for Heavy Equipment

Bearing Solutions for heavy machinery

In the demanding world of construction and heavy machinery equipment, Technymon is more than a supplier of bearings, we are a strategic partner in engineering durable and high-performance equipment. We go beyond the traditional role of a journal bushings provider, focusing on a holistic approach that tackles the unique and significant challenges faced by the heavy equipment industry.

Since 1975, Technymon has played a crucial role in manufacturing, consistently delivering exceptional products to leading equipment manufacturers and their Tier-1 suppliers. Our unwavering commitment to quality and innovation has established us as a pioneer in tribological technology, essential for the harsh conditions of this sector.

Where Our Parts Go

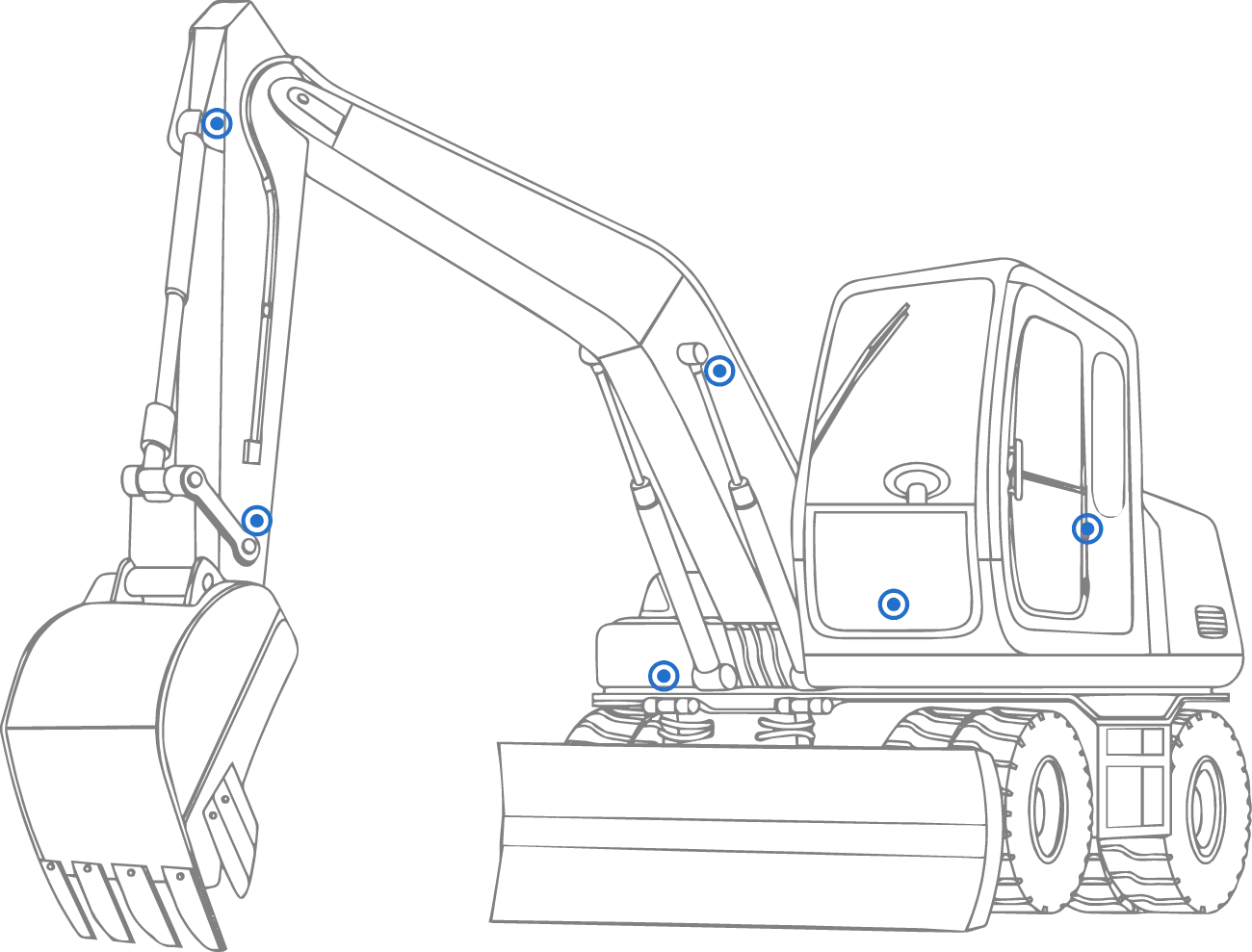

Our journal bushings are specifically engineered to thrive in the most challenging environments. They are incorporated into a wide range of heavy equipment applications, including:

- Excavators: Articulating joints, cylinder base and rod ends, bucket pivots.

- Bulldozers: Blade leveling cylinders, linkage pins.

- Backhoes: Lift cylinders, bucket pivots.

- Wheel Loaders: Articulating joints, critical clearance joints.

- Mining Equipment: Dump body pivots, axle trunnions, crawlers.

- General Applications: Articulating joints, cylinder movement pivot points, frame/walking beam trunnions, kingpins, transmissions, and more.

Get a Proposal

Technimon engineers will find the best solution for the application of our products in your production. Please fill in the simple contact form and our specialists will contact you as soon as possible.

In 1985, we established a wear test laboratory in our Italy-based plant, which has been instrumental in testing and developing solutions across various industries. This world-class research and development facility, now equipped with the latest design-modeling and simulation software, allows us to push the boundaries of performance and product quality, including for the specific and rigorous demands of construction and heavy machinery applications. Over the past decade, our Research and Development group has made significant efforts to enhance this laboratory, enabling us to meet these challenges effectively.

At Technymon, we are continuously working on the tribological aspects to improve frictional control technology. This directly translates into less wear and a longer lifespan for our sliding bearings, which is critical for equipment facing heavy loads, constant shock, and vibration. Our technical and sales teams are in constant contact with our customers worldwide, ensuring a swift response to any request.

The Technymon products incorporated into heavy equipment applications are designed with performance and durability at their core. They control friction and reduce energy loss, contributing to enhanced operational efficiency. As environmentally friendly, ROHS-compliant products, they also help minimize energy and resource requirements, aligning with modern industry standards.

Thanks to our team effort, Technymon products have become a trusted brand in the global heavy equipment industry. We supply a wide range of sliding bearings in various materials, sizes, and shapes, serving numerous applications. Through our cutting-edge technology, Technymon contributes to a healthy global environment while adding an extra edge to the reliability and longevity of heavy machinery.

Engineered for Demanding Conditions

At Technymon, we conduct continuous research to design materials that can withstand the demanding conditions of the heavy equipment industry. Our sliding bearings are engineered with the following properties, addressing key pain points for design engineers and manufacturers:

- High Load Carrying Capacity: Engineered to endure extreme loads, our bearings provide a robust solution for heavy machinery, from cranes to excavators, guaranteeing a stable and reliable operation.

- Low Coefficient of Friction: By keeping static and kinetic friction nearly identical, our bearings eliminate "stick-slip" and help equipment run more smoothly and efficiently.

- Self-Lubrication and Low Maintenance: Designed to be maintenance-free, our bearings provide an ideal solution for remote or difficult-to-service applications, eliminating the risk of early failure from poor lubrication.

- Resistance to Contamination: Engineered to withstand harsh environments, our bearings resist contamination from dirt and debris, ensuring consistent performance and preventing early wear.

- Corrosion Resistance: Built to resist rust, our bearings deliver dependable performance in wet and chemical-exposed environments, offering long-term durability in any outdoor setting.

- Shock and Vibration Absorption: By absorbing and dissipating shock and vibration, our solutions minimize operational noise and increase overall equipment stability, even in the toughest applications.

- Wide Temperature Range: Our bearings are designed to function consistently in a wide range of temperatures, from extreme heat to sub-zero cold, providing dependable performance in any climate.

- Electrical Insulation: When required, our materials can also provide electrical insulation for certain applications.

- Long Life: Designed for durability, our bearings increase component lifespan and lower overall maintenance expenses.

- Minimizing Galling and Scoring: By preventing galling and scoring, our surface materials protect components and guarantee a smooth, dependable operation.