The Shift Away from PFAs and PFOA in Sliding Bearings: EU Regulations and Safer Alternatives to PTFE

Sliding bearings, also known as plain bearings, are essential components used in machinery across industries like automotive, aerospace, and manufacturing. Known for their ability to support high loads with minimal friction, many of these bearings rely on PTFE (polytetrafluoroethylene) for its self-lubricating properties. However, with increasing concern over the environmental and health impacts of PFAs (per- and polyfluoroalkyl substances)—particularly PFOA (perfluorooctanoic acid)—the use of PTFE in sliding bearings is under growing scrutiny.

What Are PFAs and Why Are They a Concern?

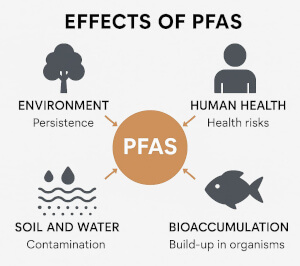

PFAs are synthetic chemicals used in a wide range of industrial and consumer applications because of their resistance to heat, water, and oil. Among them, PFOA has been commonly used in the manufacturing of PTFE, the non-stick, low-friction material found in many sliding bearings. Unfortunately, PFAs are often referred to as “forever chemicals” because they do not break down easily in the environment or in the human body.

PFAs are synthetic chemicals used in a wide range of industrial and consumer applications because of their resistance to heat, water, and oil. Among them, PFOA has been commonly used in the manufacturing of PTFE, the non-stick, low-friction material found in many sliding bearings. Unfortunately, PFAs are often referred to as “forever chemicals” because they do not break down easily in the environment or in the human body.

Exposure to PFAs, including PFOA, has been linked to various health concerns such as cancer, immune system dysfunction, hormone disruption, and developmental issues. As a result, regulatory bodies and industries are taking action to limit or eliminate their use, especially in components like sliding bearings that may come into direct contact with sensitive environments.

EU Regulations on PFOA and PFAs

The European Union has led the way in regulating PFOA and PFAs. Under the REACH framework (Registration, Evaluation, Authorisation and Restriction of Chemicals), and more specifically through the EU Persistent Organic Pollutants (POPs) Regulation, PFOA and its related compounds were officially banned in 2020, with limited exceptions.

This regulation includes strict limits on the allowable concentration of PFOA in any product, including sliding bearings that contain PTFE made using PFOA. Manufacturers and suppliers are now required to ensure compliance, driving a major shift in material selection and engineering practices.

The Role of PTFE in Sliding Bearings

PTFE has been widely used in sliding bearings due to its exceptional low-friction behavior, chemical resistance, and ability to operate in dry or lubricated conditions. Bearings with PTFE linings or composites are ideal for high-load, low-speed applications. However, traditional PTFE production methods often involve PFOA, placing these components under regulatory and environmental pressure.

Moving Away from PTFE and PFAs: Industry Innovations

To comply with regulations and support environmental responsibility, the sliding bearing industry is investing in research to replace or reformulate PTFE and eliminate the use of PFAs altogether. Current strategies include:

PFOA-Free PTFE: Some manufacturers now produce PTFE using alternative processing agents that do not contain PFOA, allowing continued use while meeting EU standards.

Non-PFA Materials: Advanced polymers and composites are being developed as direct replacements for PTFE. These materials maintain the key performance benefits while eliminating reliance on PFAs:

- Thermoplastics such as PEEK, PA, and POM offer good wear resistance and are PFAs-free.

- Metal-polymer composites use polymer liners without PFAs, bonded to steel or bronze backings.

- Fiber-reinforced composites using carbon, aramid, or glass fibers embedded in non-fluorinated resin matrices.

Performance Testing and Validation: Each new material undergoes rigorous testing to match or exceed the reliability, temperature resistance, and load capacity of traditional PTFE-based sliding bearings.

Technymon’s Role in Developing Safer Sliding Bearings

Technymon is proactively leading the transition toward PFAs-free solutions in the sliding bearing industry. Our R&D teams are actively developing and testing new bearing materials that are free from PFOA and other PFAs, without compromising performance. We are committed to sustainability, regulatory compliance, and delivering innovative products tailored to our clients' needs.

We encourage industry partners and customers to contact us to learn more about our PFAs-free sliding bearing technologies and how we can collaborate on custom solutions.

Looking Ahead: A Greener Future for Sliding Bearings

While PTFE has long been a preferred material for sliding bearings, the environmental impact of PFAs and regulatory pressures around PFOA are pushing the industry to adapt.