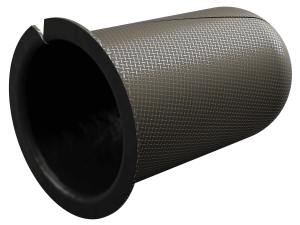

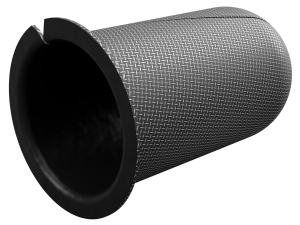

MR Sliding Bearings

The MR-1 & MR-2 Woven Metal Mesh bearings identifies a range of bearings composed of a woven wire mesh (CuSn6 or AISI 316L) within PTFE (polytetrafluoroethylene) loaded with solid lubricants.

MR-3, MR-4, MR-6/6X & MR-7 Expanded Metal Mesh bearings identifies a range of bearings composed of one of the following materials: Bronze (CuSn6), Stainless steel AISI 316L, Low carbon steel (DC04, with/without proprietary galvanic treatment), Aluminum-cladded steel, within PTFE (polytetrafluoroethylene) loaded with solid lubricants (Without lead, complying with the European Parliament’s “ELV” directive 2000/53/Ec).

The woven / expanded mesh gives the bearings the mechanical strength and the formability required to manufacture the finished parts. The loaded PTFE gives MR bearings a low friction factor and a high chemical resistance, entirely similar to those featured by pure PTFE.

Shapes and Geometries

Each Technymon Bearing is meticulously engineered to perfectly match its intended use. We consider all critical factors, including the precise fit or interference with the partnering components, to ensure optimal performance. From flanged designs to spherical shapes and integrated holes, the bearing's geometry is meticulously customized to maximize the application's overall functionality.

Applications

MR Woven Metal Mesh Bearings

The woven structure (MR-1 – CuSn6, MR-2 – Stainless steel 316L) gives the bearings the mechanical strength and the formability required to manufacture the finished parts; the loaded PTFE gives these bearings a low friction factor and a high chemical resistance, entirely similar to those features by pure PTFE.

Thanks to their composite structure, MR-1 & MR-2 bearings provide the best match of mechanical strength, thermal conductivity and low friction factor. The available products are cylindrical and flanged bearings, washers, belts and cast-to-size parts with thickness standard from 0,480 mm, 0,780 and 0,980 (0.019, 0.030 & 0.039 inch).

MR Expanded Metal Mesh Bearings

The expanded metal mesh structure (MR-3 – CuSn6, MR-4 | 6 | 6X | 7 – AlMg3, DC04 galvanized/not galvanized), Stainless steel 316L, and Al-cladded steel - Al 99.0% pure, DD11 steel type) gives the bearings the mechanical strength and the formability required to manufacture the finished parts; the loaded PTFE gives bearings a low friction factor and a high chemical resistance.

Thanks to their composite structure, the bearings provide the best match of mechanical strength, thermal conductivity and low friction factor. The available thickness standard are from 0,480 mm 0,780 and 0,980 (.019 to .039 inch).

-

MR-3

- PTFE Modified

- Bronze

- PTFE Modified

Characteristics

- Good thermal and electrical conductivity depending on the contact surface

- Negligible water absorption

- Good sizing/calibration properties

- Good corrosion resistance to aggressive media

Characteristics specific to woven metal mesh bearings:

- Higher corrosion resistance can be achieved with stainless steel version (MR-2)

- Tailored-made torque values can be achieved to eliminate play

Characteristics specific to expanded metal mesh bearings:

- Due to the expanded structure, higher quantity of PTFE can be embedded

- Higher corrosion resistance versions (up to 1000 hours Stainless steel Test) available are: MR-4, MR-6X and MR-7

- More cost efficient solutions available are steel (MR-6)

- Best material combination to match hinge material, preventing the risk of bimetallic corrosion

Woven metal mesh bearings technical data

| Maximum Specific Load Static | 100-140 N/mm2 |

|---|---|

| Maximum Specific Load Dynamic | 80-110 N/mm2 |

| Maximum Sliding Speed Dry | 1 m/s (200 fpm) |

| Service Temperature Minimum | -200°C (-328°F) |

| Service Temperature Maximum | +260°C (+500°F) |

| Coefficient of Friction | 0.02 - 0.17 |

Expanded metal mesh bearings technical data

| Maximum Specific Load Static | 100-110 N/mm2 (14500 - 16000 psi) |

|---|---|

| Maximum Specific Load Dynamic | 80-90 N/mm2 (11600 - 13000 psi) |

| Maximum Sliding Speed Dry | 1 m/s (200 fpm) |

| Service Temperature Minimum | -200°C (-328°F) |

| Service Temperature Maximum | +260°C (+500°F) |

| Coefficient of Friction Dry | 0.06 - 0.15 |