Self-Lubricated Bearings

Self‐lubricated Sliding bearings are exhibiting the ability to transfer a microscopic amount of lubrication film to the mating surface to enhance the machine performance & to reduce friction throughout its operating life, without any added grease or oils and ensuring clean, maintenance free operation in the most challenging environments.

-

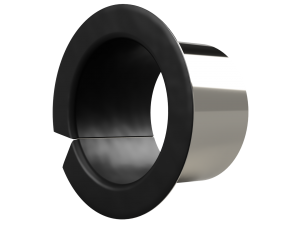

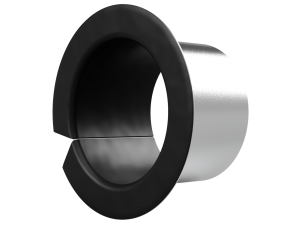

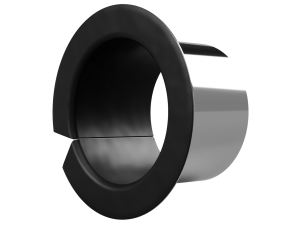

MU

- PTFE Modified

- Sintered bronze

- Low carbon steel

-

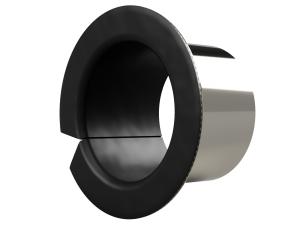

MR-1

- PTFE Modified

- Bronze

- PTFE Modified

-

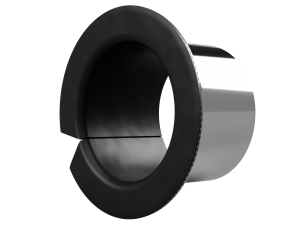

MR-5

- PTFE Modified

- Low carbon steel

- Sn or Zn protective layer

-

MR-5 AL

- PTFE Modified

- Aluminium alloy (AlMg3)

- Sn or Zn protective layer

-

MR-5 ALC

- PTFE Modified

- Aluminium cladded steel

- Sn or Zn protective layer

-

MR-5 316

- PTFE Modified

- Stainless steel

- Sn or Zn protective layer

-

ML-1

- PTFE impregnated Bronze mesh

- Low carbon steel

- Sn or Zn protective layer

-

ML-2

- PTFE impregnated Stainless steel AISI 316L mesh

- Stainless steel AISI 316L

- Sn or Zn protective layer

-

MR-2

- PTFE Modified

- Bronze

- PTFE Modified

-

MU-B

- PTFE Modified

- Sintered Bronze

- Bronze

-

MU-316

- PTFE Modified

- Sintered bronze

- Stainless Steel

-

MR-3

- PTFE Modified

- Bronze

- PTFE Modified

-

MU-J

- PTFE antifriction layer

- Sintered bronze

- Low carbon steel

-

Fritex-B

- PTFE Fabric

- Special Adhesive 60μm

- Bronze

-

HT-625

- Special Surface Treatment “Duritex ML”

- Inconel 625

-

Sintered Bronze

- Sintered Bronze

-

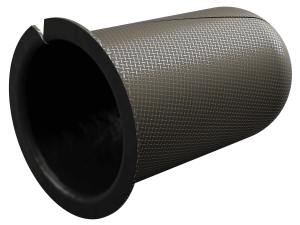

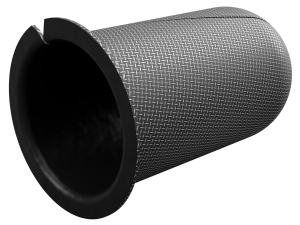

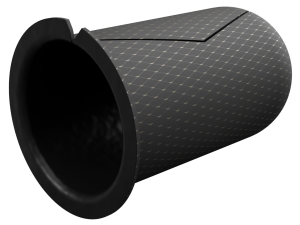

TWM

- PTFE Fibres

- Glass Fibres

- Epoxy Resin

Environmentally Friendly Performance

Unlike traditional bearings that rely on external lubricants, our self-lubricating plain bearings incorporate a unique modified polytetrafluoroethylene (PTFE) sliding layer. This innovative design offers several environmental advantages:

- Reduced Hazardous Materials;

- Extended Product Lifespan;

- Maintenance-Free Operation.

By eliminating the need for external lubricants, Technymon bearings significantly reduce the risk of environmental contamination. Traditional lubricants can leak or spill during operation or disposal, potentially harming soil, water, and wildlife. Technymon's design avoids this risk altogether.

The embedded PTFE layer provides exceptional wear resistance, extending the lifespan of plain bearings. This reduces the need for frequent replacements, minimizing waste generation and resource consumption.

Technymon's self-lubricating design eliminates the need for regular lubrication procedures. This not only reduces maintenance costs but also minimizes the environmental impact associated with the production, transportation, and disposal of lubrication products.

By choosing Technymon self-lubricating bearings, you're not just making a smart performance choice, you're also making a positive contribution to a greener future.