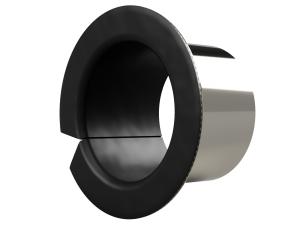

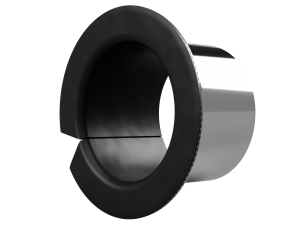

ML Sliding Bearings

ML defines a multi-layer composite material dedicated for manufacturing of sliding bearings for dry-lubricating applications.

Sliding layer is made of expanded metal mesh available in various solutions (bronze, stainless steel, aluminium-cladded steel) impregnated with PTFE loaded with solid lulbricants. Backing layer is constituted by steel or aluminium-cladded steel according to request.

Benefits provided by ML material structure include accurate sizing capabilities with the ability to sustain high loads thanks to backing support.

Shapes and Geometries

At Technymon, we understand a one-size-fits-all approach doesn't fly for bearings. That's why every bearing we design is meticulously tailored to its specific application.We go beyond basic cylindrical shapes. Flanges, spherical profiles, and strategically placed holes are all part of our design toolbox to enhance performance metrics like load capacity, stability, and self-alignment depending on the application's needs. Technymon bearings integrate seamlessly into your design, maximizing overall application performance and efficiency.

Applications

ML Sliding Bearings

Characteristics

- Extra-thick sliding layer with woven / expanded metal mesh support embedded with PTFE helps in edge loading

- High calibration / sizing assembly to compensate higher tolerances of hinge hole and pin

- Electrically conductive to enable EDP (Electro-Phoretic Deposition), also available with notches

- Right fit according to requirement to achieve desired torque value

- Noise-free / smooth operation in assembly

Technical Data

| Maximum Specific Load Static | 150-300 N/mm2 |

|---|---|

| Maximum Specific Load Dynamic | 100-170 N/mm2 |

| Maximum Speed Dry | 1 m/s (200 fpm) |

| Service Temperature Minimum | -200°C (-328°F) |

| Service Temperature Maximum | +180°C (+356°F) |

| Service Temperature Intermittent | +260°C (+500°F) |

| Coefficient of Friction Dry | 0.07 - 0.17 |