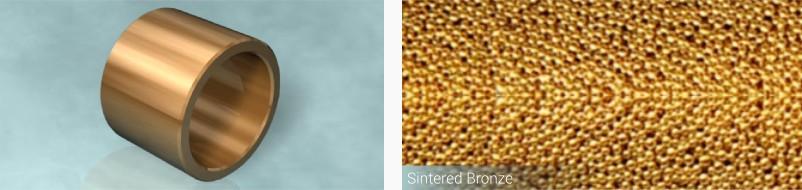

Sintered Bronze Self-Lubricated Bearings

The bush in Sintered Bronze give a wide range of applications, is realized with a powder of bronze sintered, calibrated and impregnated into specific oil (volume of impregnation of 25% ÷ 29% as per DIN 30910 Sint A50). During the application, this kind of material, thanks’ to the oil impregnation, developes a film of lubricant oil, between the shaft and the bush.

Operating Conditions

-

DRY -

OIL -

GREASE -

WATER -

PROCESS

FLUID

Please, fill this form for getting current Pricesheet and/or Drawings in DWG format. We will send you all files on your email.

All fields, which marked by an asterisk (*), are required.

Thank you for your interest in our company.

Characteristics

- Dry Self-lubricating

- Good load capacity

- Easy to assembly

- Minimum overall dimensions

- Standard items widely available

- Special items on demand

- Wide range of operating temperature

- Minimized wear and good service life

Chemical Composition

| Element | Cu | Sn | Other |

|---|---|---|---|

| Min | Rest | 8% | 2% |

| Max | Rest | 10.5% | 2% |

Technical Data

| Maximum Specific Load Static | 10 N/mm2 |

|---|---|

| Maximum Specific Load Dynamic | 5 N/mm2 |

| Maximum Sliding Speed | 10 m/s (1970 fpm) |

| Friction Factor | 0,08 ÷ 0,12 |

| Service Temperature Minimum | -5°C (+23°F) |

| Service Temperature Maximum | +90°C (+194°F) |

| Shaft Roughness (Suggested) | ≤0,2 Ra |

| Shaft Hardness (Suggested) | >350 Hb |

| Density Min. | 5,6 g/cm3 |

| Density Max. | 6,0 g/cm3 |

| Porosity Min. | 22,5 % Vpor/Vtot |

| Porosity Max. | 27,5 % Vpor/Vtot |

| Hardness Min. | 30 HB |