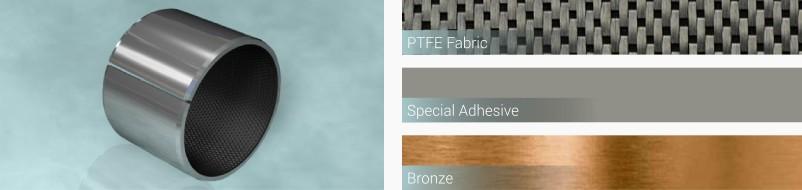

Fritex-B Self-Lubricated Bearings

Multilayer bushing (dry Sliding Bearings) Fritex-B is a three layer composite product.

- PTFE Fabric with special fibres of 0,40 mm thickness.

- Special Adhesive 60μm thickness.

- Bronze CuSn8P from 0,50 to 2,70 mm thick depending on the size of the bush.

Operating Conditions

-

DRY -

OIL -

GREASE -

WATER -

PROCESS

FLUID

Please, fill this form for getting current Pricesheet and/or Drawings in DWG format. We will send you all files on your email.

All fields, which marked by an asterisk (*), are required.

Thank you for your interest in our company.

Structure of the composite material

| Layer | Average analyses of the material | Thickness of layer |

|---|---|---|

| Sliding layer | PTFE Fabric | 0,40 mm |

| Intermediate layer | Special Adhesive | 60 μm |

| Supporting shell | Bronze CuSn8P

|

0,50 ÷ 2,70 mm

|

Characteristics

Fritex-B Structure combines in the best way the mechanical strength and the chemical resistance of bronze, and PTFE low friction characteristics. The performance given without lubricants are the following:

Working surface acceptable specific static pressure until 200 N/mm2

Working surface acceptable specific dynamic pressure until 150 N/mm2

Maximum sliding speed: 1,5 m/s (300 fpm)

Working temperature from: -100°C to +260° C (-148°F to +500°F)

Friction factor from 0,03 ÷ 0,15

High chemical resistance to industrial fluids and gases. We recommend to make previous test for new application / project.

Special Items

Apart from bushings and thrust washers the Fritex-B can be supplied as many other technical items, between them we indicate the followings:

- Bushings and washers with dimensions on request

- Special items at customer’s drawing.

Mounting

Base procedure for bushings mounting is to force them into their seats; there are some suggestion to follow:

- Machine a 1 mm seat lead - in with an angle of 20° (±5°)

- Clean and burr the pieces to couple

- Lubricate external bushing surface before mounting

- Check alignment between seat and bushing centre lines

- When 2 bushing are needed their junctions must be aligned

- Use a proper sized mandrel when possible.

- Mounting can be done with hydraulic or mechanical tools.

The mounting force (F) in Newton is shown in the attached table.

| Bushing Nominal Thickness 0,50 ÷ 1,00 mm | F = 300 x L (Length of bush) |

| Bushing Nominal Thickness 1,00 ÷ 1,50 mm | F = 500 x L (Length of bush) |

| Bushing Nominal Thickness 1,50 ÷ 2,00 mm | F = 700 x L (Length of bush) |

| Bushing Nominal Thickness 2,00 ÷ 2,50 mm | F = 900 x L (Length of bush) |

When mounting larger bushes it is advisable to use a mounting tool to support the bush. The tool diameter should be 0,3 ÷ 0,4 mm more than the bush diameter. If the bush is secured by using an adhesive, care must be taken to ensure that good quality adhesive are used and that it does not get onto the sliding surface.