MP-340

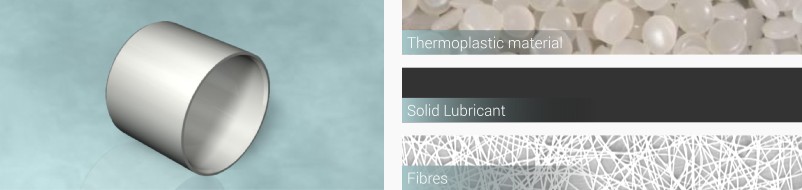

MP-340 is a thermoplastic material with a wire of fibers mixed with solid lubricants. The product has a good wear resistance, low water absorption and high loads resistant .There are several applications, ranging from office supplies, to medical equipment, pneumatic cylinders, hinges, rudder bars, etc. The MP-340 series includes cylindrical and flanged bearings as well as washers, and special parts are available on demand.

Operating Conditions

|

Dry |

Oil |

Grease |

Water |

Process fluid |

|---|---|---|---|---|

| Good | Good | Good | Good | Good |

Availability

Characteristics

- Dry self-lubrications

- Good wear resistance

- Low water absorption

- Good chemical resistant

- Easy to assembly

- Wide range of standard items available

- Special items on demand

General Properties

| Density | 1,45 g/cm3 (DIN-53479 ASTM-D792) |

|---|---|

| Max moisture absorption in water at 24 h (23°C) | 0,15 % (ISO-62) |

| Coefficient of sliding friction, dynamic | 0,08 ÷ 0,20 |

| P x V Value | 0,43 N/mm2 (Dry) |

| Color | White |

Mechanical properties

| Tensile strength (23 °C) | 120 N/mm2 (ISO-527) |

|---|---|

| Modulus of elasticity (23 °C) | 5300 N/mm2 (ISO-527R) |

| Elongation at break (23 °C) | 2% (ISO-527) |

| Izod – Impact strength (notched) (23 °C) | 90 J/m (ASTM D256-A) |

| Charpy – Impact strength (unnotched) (23 °C) | 43 Kj/m2 (ISO 179-1) |

| Charpy – Impact strength (notched) (23 °C) | 8 Kj/m2 (ISO 179-1) |

| Max surface speed (rotating) | 1,0 m/s |

| Max surface speed (linear) | 3 m/s |

| Max static surface pressure | 50 N/mm2 |

Physical and thermal properties

| Max long term application temperature | +130°C |

|---|---|

| Min long term application temperature | -40°C |

| Coefficient of thermal expansion (+30°C +100°C) | 4 K-1 * 10-5 (DIN53752) |

Electrical properties

| Specific volume resistance | >1013cm (DIN53482) |

|---|---|

| Surface resistance | >1012cm (DIN53482) |