Ball Seats for Ball Joints

Technymon Global Bearing Technologies Presents a low friction, maintenance free Self-lubricated & Pre-lubricated Bearing Material with a desired shape/profile with close tolerance of ‘‘Ball Seats’’ based on Customer requirement to Match the extreme working conditions of Ball joints.

Introduction:

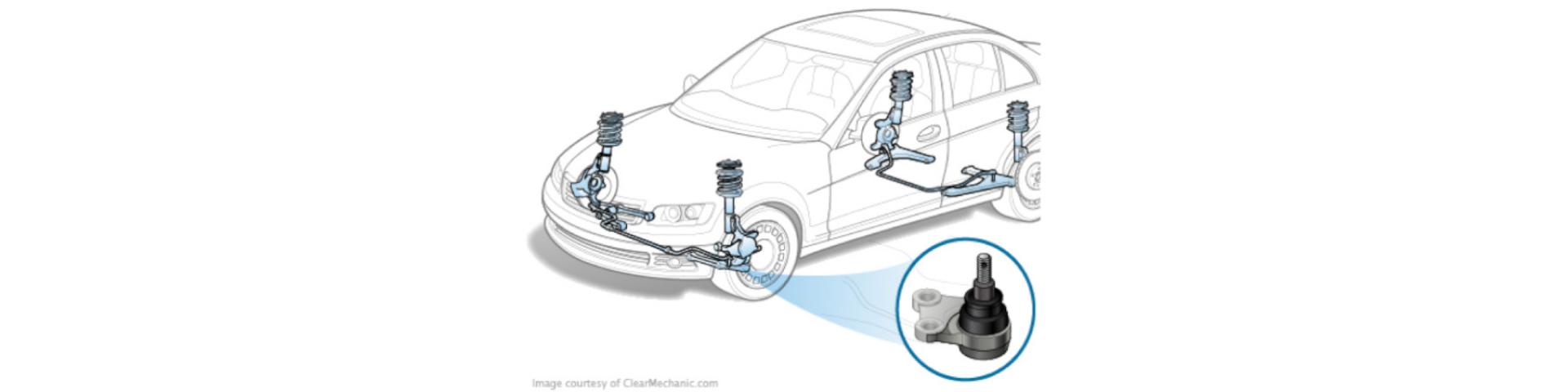

In addition to low frictional and wear properties, the right shape/profile of Ball seats facilitate the performance under high loads, vibration and articulated speeds while resisting the uneven shocks coming from actual/practical operation.

A Global manufacturer of Steering & Suspension Components for four wheelers was looking to develop durable/reliable Ball seats for their high performing Ball joints with Articulation load of: 20,000 Kg, Articulation angle: ±20⁰, Articulation frequency: 2 Hz, Radial load: ±4000 Kg, Radial Frequency: 0.5 Hz, Rotational load: ±40Kg, Rotational frequency: 0.7 Hz, Cycle Requirement: 5, 00,000 min. to 10, 00,000 max. Working Temperature: -40⁰C to 80⁰C, Lift up: 0.3 @ 300 Kg.

To meet the customer high standard requirment of their Ball Joints, customer was in need of quality bearing material with exceptional realiability/durability. The Ball Joint required two Ball Seats in order to support the Ball pin, mainly named as upper Ball Seat and Lower Ball seat.

The customer’s greatest need was low frictional Self or Pre-Lubricated material with good shock absorbing capacity.

Conclusion:

So after Various Testing MX material proven to be best performing material in this application, offering High Shock and Vibration resistance with low frictional properties combining with Grease lubrication.

Additional Characteristics:

- Good load capacity

- Water-repellent (no swelling)

- Minimized wear and excellent service life

- Little maintenance required

- Insensitive to shocks

- Easy lubricated

- Wide range of operating temperature

- Compact and light

- Easy mounting

Technymon Global Bearing technologies also provide Ball Seats in MU Material to variuos customer depending on their Ball Joints operational requirments which provides Sel-Lubrication Property with extremely low coefficient of friction due to additional fillers in PTFE compounding.