MP-310

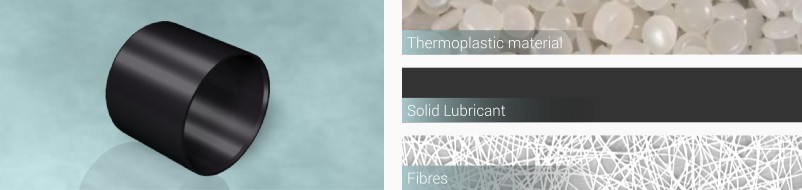

MP-310 is a thermoplastic material with a wire of fibers mixed with solid lubricants. The product has an optimal wear resistance also with high loads, good dirt resistant and good resistant to edge loads. There are several applications, ranging from office supplies, to medical equipment, pneumatic cylinders, hinges, rudder bars, etc. The MP-310 series includes cylindrical and flanged bearings as well as washers, and special parts are available on demand.

Operating Conditions

|

Dry |

Oil |

Grease |

Water |

Process fluid |

|---|---|---|---|---|

| Good | Good | Good | Fair | Fair |

Availability

Characteristics

- Dry self-lubrications

- Optimal wear resistance also with high loads

- Minimized wear and excellent service life

- Good chemical strength

- Easy to assembly

- Wide range of standard items available

- Special items on demand

General Properties

| Density | 1,26 g/cm3 (DIN-53479 ASTM-D792) |

|---|---|

| Max moisture absorption in water at 24 h (23°C) | 1,0 % (ISO-62) |

| Coefficient of sliding friction, dynamic | 0,24 ÷ 0,29 |

| P x V Value | 0,55 N/mm2 (Dry) |

| Color | Black |

Mechanical properties

| Tensile strength (23 °C) | 90 N/mm2 (ISO-527) |

|---|---|

| Modulus of elasticity (23 °C) | 4800 N/mm2 (ISO-527R) |

| Elongation at break (23 °C) | 3,10% (ISO-527) |

| Izod – Impact strength (notched) (23 °C) | 40 J/m (ASTM D256-A) |

| Charpy – Impact strength (unnotched) (23 °C) | 30 Kj/m2 (ISO 179-1) |

| Charpy – Impact strength (notched) (23 °C) | 4 Kj/m2 (ISO 179-1) |

| Max surface speed (rotating) | 1,0 m/s |

| Max surface speed (linear) | 5 m/s |

| Max static surface pressure | 70 N/mm2 |

Physical and thermal properties

| Max long term application temperature | +135°C |

|---|---|

| Min long term application temperature | -40°C |

| Coefficient of thermal expansion (+30°C +100°C) | 4 K-1 * 10-5 (DIN53752) |

Electrical properties

| Specific volume resistance | >1015cm (DIN53482) |

|---|---|

| Surface resistance | >1014cm (DIN53482) |